![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

68 Cards in this Set

- Front

- Back

|

Ceramics type of bond |

Ionic and Covalent |

|

|

Ceramic Structure: 2 parts |

Cations (+) Anion (-) |

|

|

crystalline are more....bond type |

ionic |

|

|

amorphous are more....bond type |

covalent |

|

|

Ceramic structure types (3) |

Ax (NaCl) AmXp (CaFl2) AmBnZp (BaTiO3) |

|

|

Packing factor is function of.... |

size of A, B and x and electrically neutral. Charged ions make it difficult to pack close |

|

|

2 Ceramic Groups |

Traditional & Modern |

|

|

The highest Tmp (equaTion) |

|

|

|

Ceramics |

Pro: Very high specific properties, corrosion resistant, high use temper, the hardest, formable Con: no toughness, lowest Kic, porosity, $$$, low impact resistance, difficult to machine |

|

|

Ax has how many atoms? |

2 |

|

|

structure for CaF2 |

ax2 |

|

|

BaTiO3 ceramic structure |

AmBnXf |

|

|

4 Ceramic defects |

Point, Line, Surface, Volume |

|

|

Point Defects |

vacancy, interstitial, substitutional |

|

|

Line Defects |

Edge, screw |

|

|

Surface Defects |

desire small grains, increase grain boundary |

|

|

Volume Defects |

porosity |

|

|

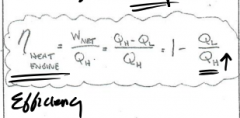

Advanced Ceramics (4) |

Heat Engine, Optical Fiber, Ceramic Ball Bearings, Microelectromechanical Systems (MEMS) |

|

|

Advanced Ceramic: Optical Fiber |

High purity silica, very clean, no scattering of light |

|

|

What is a polymer? |

Large organic chains or molecules Examples: rubber, wood, oild |

|

|

What does it mean? "Poly" "mer" |

Many repeating unit |

|

|

Isomerism |

Same compound but with a different structure |

|

|

Type of chains and type of bonding of Polymer |

Linear: covalent & vander waal Branched: covalent & vander waal Crosslinked: covalent |

|

|

Polymerization |

joining mers via current, heat, pressure, etc |

|

|

Addition |

Thermoplastics, same mers,sequential linear, fast, spontaneous |

|

|

Condensation |

Thermosets, different mers, slow, by product, cross-linked polymers |

|

|

Degree of polymerization "n" |

average # of mers in a chain n=Molecular weight (given)/total molecular weight of atoms |

|

|

True or False. As chain extend in length does Tmp ^, Sy^, hardness ^ and E^? |

True |

|

|

Crystallinity |

chain alignment "ribbons" or crystals |

|

|

Why do we want crystallinity? |

Chains become closer together and vander wall bond strength is increased, easiest for long chains, linear to form crystals, slow cooling from melt |

|

|

Polymers |

Pro: low density, cheap, strong eough, low tmp, recycle Con: poor mechanical properties, weak, creep, embrittle, low Tmp, low impact resistance, temp sensitive, UV sensitive |

|

|

Thermoplastics |

liquify/melt, linear chains, copoymer, addition polymerization, viscoelastic Properties: melt, ductile, low Sy and E, formable |

|

|

Thermosets |

permanently set, do not melt, char or burn, network, covalent bonds, retationally rigit, brittle, condensation plymerization, elastomers Properties: brittle, high Sy, E, low Kic |

|

|

Traditional Ceramics |

Clay based, brick, tile, glasses, silicate, High temper, abrasives |

|

|

Modern Ceramics |

High purity powder, controlled micro structure, C, graphite, diamond, strengthening mech? sw, sss, gs, ds |

|

|

Polymer molecules can be characterized by: |

Size, Shape, Structure |

|

|

Saturated bonds |

Uses up all bonding |

|

|

Unsaturated bonds |

Double bonds or greater were used |

|

|

Monomers |

Double unsaturated structure |

|

|

Thermosets have what kind of molecular configuration? |

Crosslinked |

|

|

Thermoplastics have what kind of molecular configuration? |

Linear and Branched |

|

|

What are the 3 major polymer molecular configurations? |

isotactic, syndiotactic and atactic |

|

|

Isotactic are groups of the... |

same side of chain |

|

|

Syndiotactics are groups of the... |

alternate sides |

|

|

Atactic are groups of the... |

randomly positioned |

|

|

Viscoelastic: As strain rates increases |

brittle behavior, chain have no time to slide |

|

|

Viscoelastic: As strain rates decreases |

ductile behavior |

|

|

Glass Transition Temperature |

Temp where the material goes from rubber to brittle |

|

|

Additive types |

Pigments, stabilizers, plasticize, reinforcement, antistatic, flame retardants |

|

|

Polymer properties affected by |

degree of polymerization, bond type, chain structure, e, temp, environment, additives |

|

|

Copolymer |

two or more monomers polymerized together |

|

|

Elastic Region |

The amorphous region is unkinking, elongation of the chains, crystallites thicken due bonding and stretching |

|

|

Plastic Region at yield |

Necking, tilting of crystallites/chain folds, crystalline region aligning, vander waals breaking |

|

|

Plastic Region #3 |

Crystalline blcok segments separate from lamellae, vander waals breaking |

|

|

Plastic Region #4 |

Continued block sliding and separation, tie chains are aligned with load, fibrillar structure, vander waals and covalent bonds break |

|

|

Particle reinforced |

large particle, dispersion strengthened |

|

|

Fiber reinforced |

continuous(aligned) and discontinuous (short), fiber types whiskers, fibers, wires |

|

|

Structural |

Laminates, sandwich panels |

|

|

Composites are |

two or more materials that synergistically combine to give optimum properties that neither material count provide alone |

|

|

Matrix |

soft, ductile, adhere to fiber/ppt, transfer shear stress |

|

|

Fiber |

Hard, tough, strong, stiff, corrosion resistant, low density, $$ |

|

|

Composites |

Pros: low density, high E, the highest specific properties, fatigue resistance, tailorable Cons: low damage tolerance, toxic, moisture absorption, $$$, difficult to process, |

|

|

Cite the overall mechanism common to all 4 strengthening mechanisms |

stopping of slowing dislocation motion |

|

|

What is the mechanism of plastic deformation |

dislocation motion |

|

|

What is the mechanism of elastic deformation |

bond stretching |

|

|

What are 3 steps in precipitation hardening and describe |

Solution treat: heat up allow to 100% alpha Quench: rapidly cool below solidus Age: at room temp or below solidus |

|

|

One requirement for age hardening to occur |

decreasing solubility with temp |

|

|

Vulcanization |

is a chemical process for converting natural rubber or related polymers into more durable materials by the addition of sulfur or other equivalent curatives or accelerators |